Francisco Suárez-Ruiz and Quang-Cuong Pham, Nanyang Technological University, Singapore

Putting together flat-pack furniture can be arduous and frustrating. So why not let robots do it instead? A pair of robot arms can now assemble an IKEA chair in just a few minutes, and without arguing too.

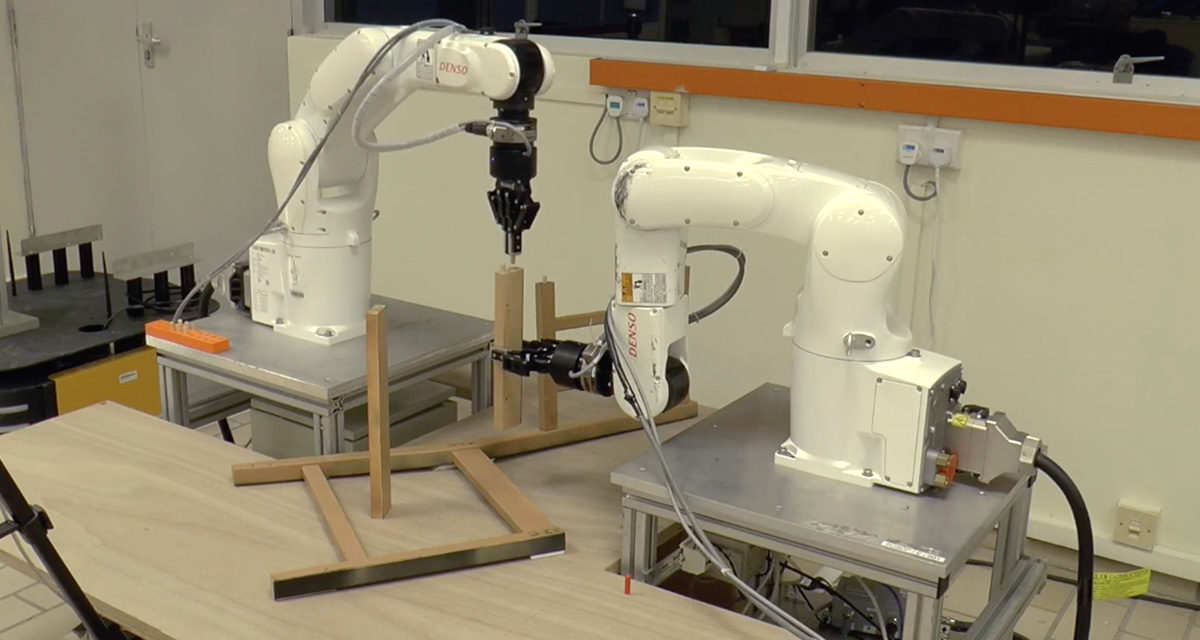

The setup consists of two industrial robot arms with grippers and force sensors, all watched over by a 3D camera. To start things off, parts of an IKEA STEFAN chair are jumbled up and dumped in front of the arms. The camera then takes a snapshot of the scene and relays each part’s location to the robotic arms.

The robots had to be pre-programmed with information about how the parts fit together and in what order, but armed with that data they determined their movements automatically, using the force sensors to make sure nothing was broken. “In our future work, we are planning to incorporate AI so that the robot can figure out by itself the sequence of instructions,” says Quang-Cuong Pham at Nanyang Technological University in Singapore, one of the creators of the system.

For now, the arms are only able to piece together furniture using dowels that fit into pre-drilled holes. They place the dowels near the holes and move in a spiral motion until they slot in. Pham says that this is the most difficult part, since the dowels and holes are so small that the 3D camera can’t determine their positions precisely enough.

The robot arms take a total of 20 minutes to put together the STEFAN chair. Localising the parts takes only 3 seconds, planning the motion takes around 11 minutes, and actually assembling the chair takes about 9 minutes.

The chair wasn’t quite useable at the end of the process. “There are a few steps that we have not completed, such as putting in the screws,” says Pham. But who hasn’t found a few unused screws after a day of assembling IKEA furniture?